Illinois-based American Litho, a leader in data-driven direct marketing solutions, specializes in producing personalized and impactful direct mail campaigns for businesses across various industries.

They aimed to maintain their competitive edge in a rapidly evolving market by replacing many of its aging Prosper print systems with more advanced and efficient technology.

Adapting for a Competitive Advantage

Faced with improving productivity and reducing operational costs on an existing production line, American Litho sought an inline variable data printing solution that could enhance print quality, minimize downtime, minimize paper waste, and decrease refurbishment expenses.

Solution

Elevating Direct Mail Production with X-Bar

After evaluating other technologies, American Litho concluded that Kao Collins and its X-BAR print module were the best solution.

The modular design of the Kao Collins X-BAR print module integrated easily with existing equipment on the company’s existing analog presses.

Upgrading the inline system improved production of personalized content, beyond basic recipient information, significantly enhancing the impact of projects.

Measurable Cost Savings

- Eliminated ongoing refurbishment costs of aging Prosper equipment.

- The 9-inch print bars improved production times.

- Cut ink consumption

- Reduced waste

- Make adjustments without interrupting press operations.

Increased Production Speed and Efficiency

- Print full-width letters without stitching

- Created more production capacity

- Setup adjustments could be made without interrupting press operations, reducing waste during changeovers.

The Power of Universal Control

American Litho uses the Universal Controller to drive multiple print modules on their production line. In fact, the X-BAR and Universal Controller help them overcome production challenges by providing key advantages

Ease of Operation

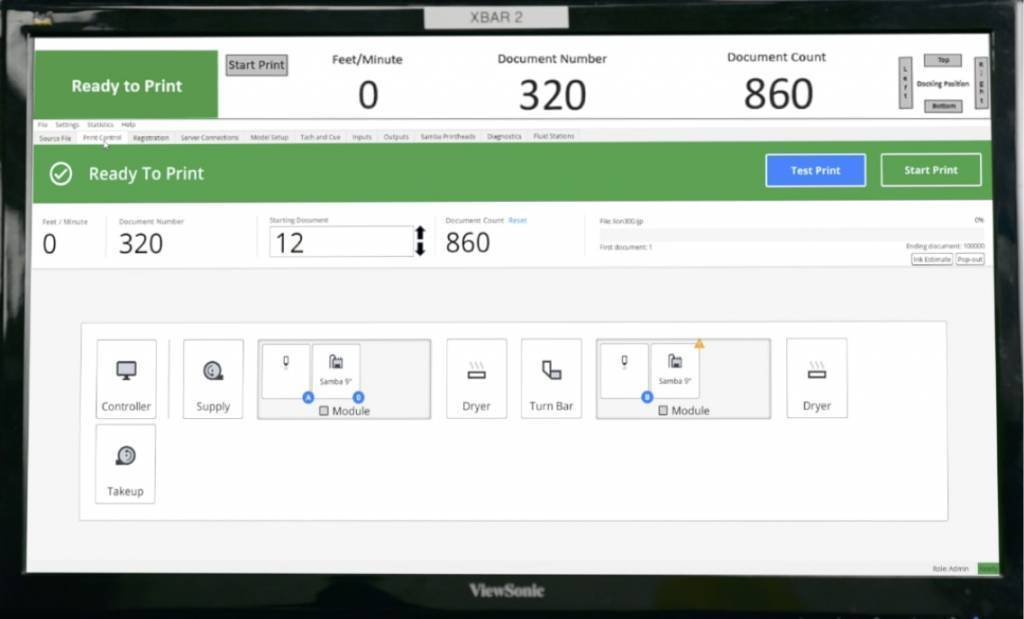

The Universal Controller is capable of driving up to 16 print modules on a production line.

Multiple tach and cue inputs and outputs offer greater control for improved production.

Validation functions connections between the controller and printing components save time during set-up and operation.

Results

Business Booms,

Costs Shrink

American Litho’s investment in the X-BAR yielded impressive results.

- Saved ~$1M in refurbishment costs in year one

- 9” XBAR modules cut stitching to drive business growth

- 40-50% decrease in ink consumption

- Zero charge shorts and streakers ensured maximum uptime

- Significant waste reduction

- Reduced power consumption saves money

“Within the first year, we saved approximately $1 million in refurbishment costs.”

– Mickey Baraban, Digital Imaging Manager

X-BAR

The X-BAR print module, powered by Fujifilm Inkjet Technology, is a cutting-edge solution for inline printing of variable data on offset or flexo printers. It offers high throughput, maximum uptime, premium print quality, and necessary flexibility.

X-BAR enhances efficiency, reduces costs, meets dynamic market demands, ensures adaptability, and supports eco-friendly practices.

- Print Width: Available in 4.7″ and 9.4″ options.

- Print Arrays: Two arrays of 3 Samba G3L printheads or one array of 6 Samba G3L printheads.

- Nozzles per Array: 5,632 or 11,264, depending on the configuration.

- Cross Process DPI: 1200 for both configurations.

- Process Resolution: Options include 300/600/600i/1200 dpi or 300/600/1200 dpi, providing versatility in print quality.

- Dimensions and Weight: Compact design with varying dimensions and weights for different configurations, ensuring space efficiency.

- Monochrome System: Supports black and spot color printing.

- Speed: Capable of printing at 1000 fpm at 1200 x 600 dpi or 1000 fpm at 1200 x 300 dpi.

- Variable Data: Supports variable data printing for customized output.

“We’re able to print full letters without stitching which added more business.”

– Mickey Baraban, Digital Imaging Manager

Universal Controller

The Universal Controller is capable of driving up to 16 print modules on a production line. The Windows-based Universal Controller powers precision printing with streamlined operation and enhanced performance of X-BAR print modules. Our designers built the user-friendly controller from the ground up, focused on maximizing precision and throughput.

- No Licensing Fees: No ongoing costs or dongles

- Compatibility: Operates X-BAR and Versamark DS6240 printheads

- Read and Print: Simplified operation requires minimal training

- GUI Interface: A user-friendly graphical interface similar to the CS410

- Auto Detect: Validate connections between controller and RIPs

- Tach and Cue Board: Up to 8 inputs and 32 outputs ensure precise control and synchronization.

- Dual RIP: Allow one 9.3” X-BAR print module to print 2 RIPs

- Modeling: Build press models and associated devices

- Expanded features: Ink usage estimation, historical log support, and more

“We evaluated many other technologies, but the Kao Collins X-Bar was flexible and easy to work with.”

– Mickey Baraban, Digital Imaging Manager